When using the inspection tools like thread gauges, it is important to know how to use the tool correctly. It looks like a very easy to use tool and anyone could use the tool without much training. True, this is one of the simplest inspection tools that you will come across but if you do not know how to make use of your tool, you could end up damaging the tool and the components that you inspect will also not be tested properly. In other words, you cannot rely on the inspection results when you do not know how to make correct use of the tool. Before you use the UN thread gauges it is important that you pay attention to the following factors.

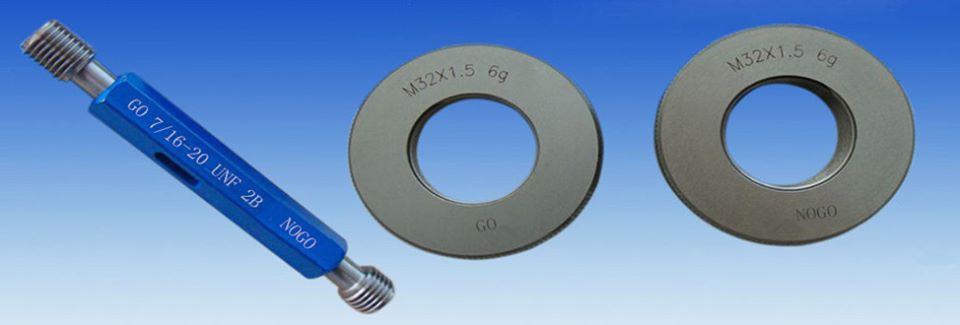

Each time you pick up your Whitworth thread gauge or any other thread gauge, make sure that you check the markings. If you happen to use the wrong thread gauge, you could make mistakes with the inspection process. The readings of your inspection will not be accurate.

If the thread gauges are not properly labeled then you need to calibrate the tool and label it correctly so that you do not use the wrong tool. If you happen to make use of the wrong thread gauges, you should not exert undue force while using the tool. The thread should run smoothly when you are using the GO thread. If you are using NOGO thread, you should stop with a maximum of two turns once you sense the thread is tight. Trying to drive the thread further will damage the NOGO thread making the tool useless.

It is also important to label the plastic tubes in which the thread gauge is stored. Often operators check the label in the storage tube and do not check the label in the tool and this could lead to inconsistencies and inaccuracies in the readings and inspection results. After using make it a practice to put back the tool in the right holder.

It is recommended that the thread gauges are calibrated regularly. This will ensure that your thread gauges are in good condition and that you could rely on the inspection readings. It would be a mistake not to have a regular calibration schedule for calibrating all the thread gauges. As you would have noticed your thread gauges are subjected to a very high level of wear and tear. This could make the thread gauge wear out easily and faster than you expect. When you have a regular calibration schedule, you will be able to find out whether the tool is worn out or whether it is in usable condition. Many think that it is sufficient to get the calibration certificate when they buy the tool and totally forget about calibration. You should not make such mistakes. Regularly calibrated tool will give you the most accurate inspection readings. Stay away from all the above mistakes and you would be able to get the most accurate thread gauge inspection results.

Zafer

Zafer