Quality cutting tools are in high demand as

industrialization and globalization advances. Since we have so many types of

machinery in our homes and offices, we all must know something about operating

the necessary tools.

The tools are

created from high-end materials, including carbon, cemented carbide, ceramics tool,

cubic boron nitride, and aluminum among many other metals.

Types of Quality Cutting Tools

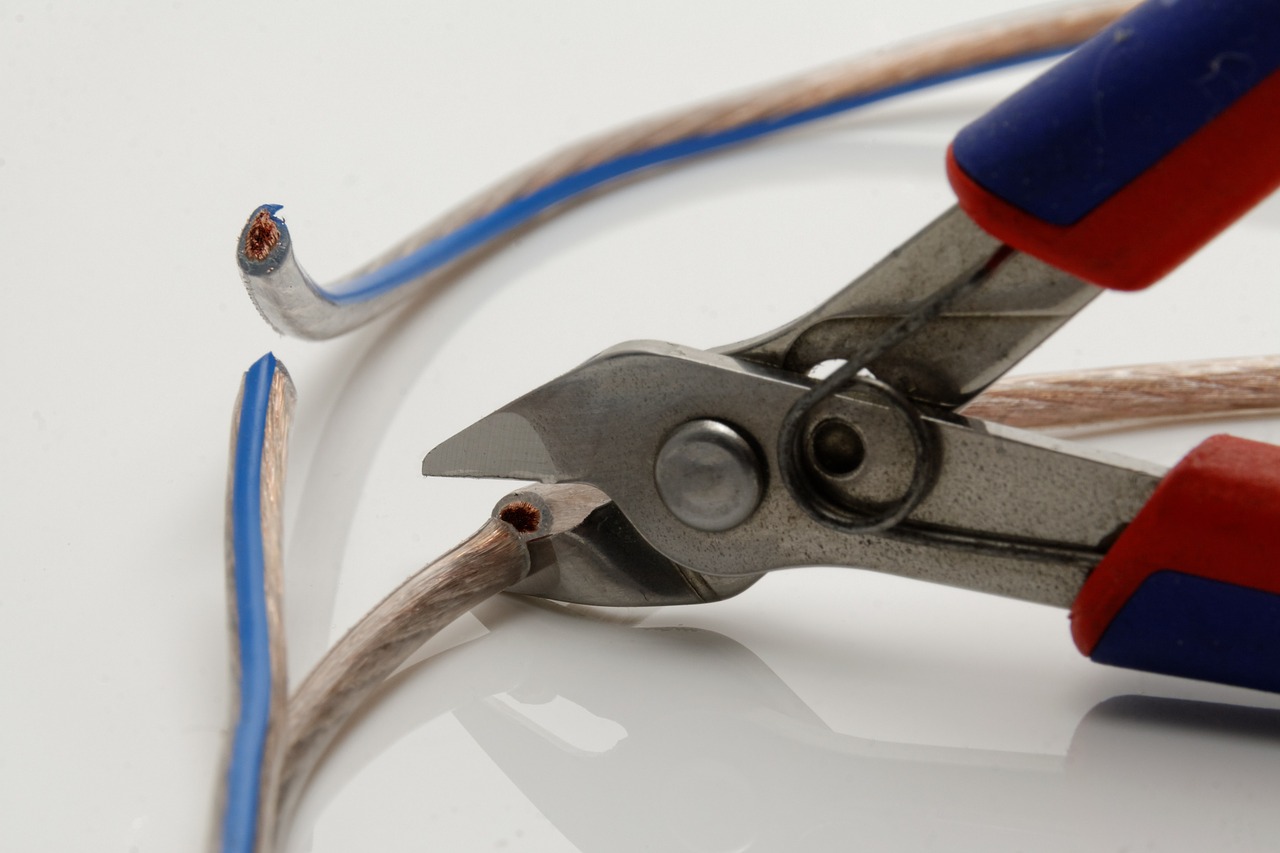

Direct Cutting Tool

– This kind of tool is sturdy and attacks directly to cut the surface. It has a

blade or sharp knife that cuts through the surface, be it glass, wood, metal, or

steel. It is widely used in factories that manufacture furniture by cutting

down raw material. For example, a knife or saw can be good examples of this.

Drilling Quality Cutting Tool

– Apparently, there are two kinds of drills. One is the drill driver which is

operated automatically to dig holes into hard surfaces and usually helps to put

nobs and screws. While the second one is a hammer drill, which can be switched

from manual use to automatic depending on what kind of surface you are drilling

on. It usually works fantastic to drill holes into concrete walls and rocks.

Reamer Tool – A reamer and

drilling machine go hand in hand in most of the cases. Hence, it is important

to note here that while a drilling tool helps in initiating a hole on a hard

surface, it the job of the reamer to enlarge it. One can say that a reamer is

more powerful and sturdy than a drilling tool. It uses hard metal or diamond

with a swirly or rotating design.

Milling Tools – This is a set of

quality cutting tools that covers one unit of cutting tools. The fundamental

difference between a milling tool and other tools is that a milling tool has sharp

cutting edges on its body while others have them at their endpoint. The most

common milling tools are roughing end mill, slab mill, wood rough cutter, slab

cutter, dovetail cutter, hobbing cutter slide, and face cutter, etc. Each one

has a different shape and size, but inevitably performs the same function, i.e.

cutting out a chunk of material from the hole.

Broach Tool – This kind of

cutting tool is widespread in a mechanic’s toolbox. It looks like a long slim

rod with rotatory designs on its body. Each layer of the model is sharp and

gives a clean hole into the surface that you are digging. It is mostly used to

provide a square or triangle piece of machine or metal with a round hole.

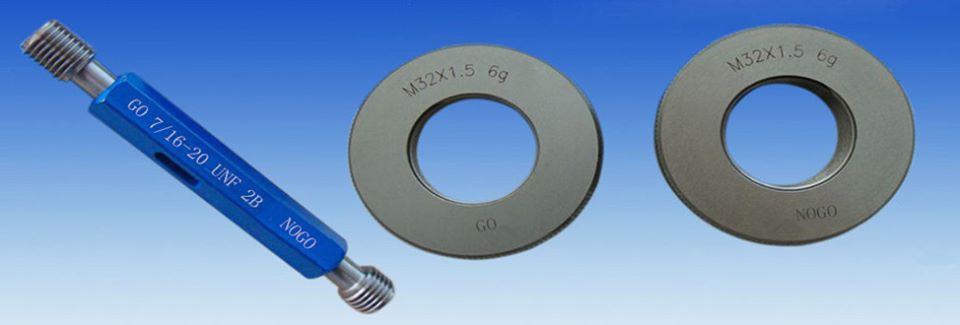

Tap Cutting Tool

– It is used to cut an inside thread with a female thread, and this is called as

a tap cutting tool. The purpose of this tool is to reduce and create screw

threads from previously used threads. Hence, to select

the right tap cutting tools, one must know the length and breadth of the cutting

tool that they are going to need.

Where Can You Get Quality Cutting Tools?

One cannot deny

the fact that the number of manufacturers in the cutting tool industry is less.

The most trusted ones are Taegu Tec LTD, Mitsubishi Materials Corporation,

Kennametal, ESCAR and Hitachi metals, etc. Apart from these top names, you will

also find some tools in your local market, which may be cost-effective to you

and your purpose of buying the same.

Conclusion

To sum up, we would

like to put out a few factors before you look for quality cutting tools, i.e.

features like the history of the company, the customer reviews, and the test of

time works the best.

Zac

Zac