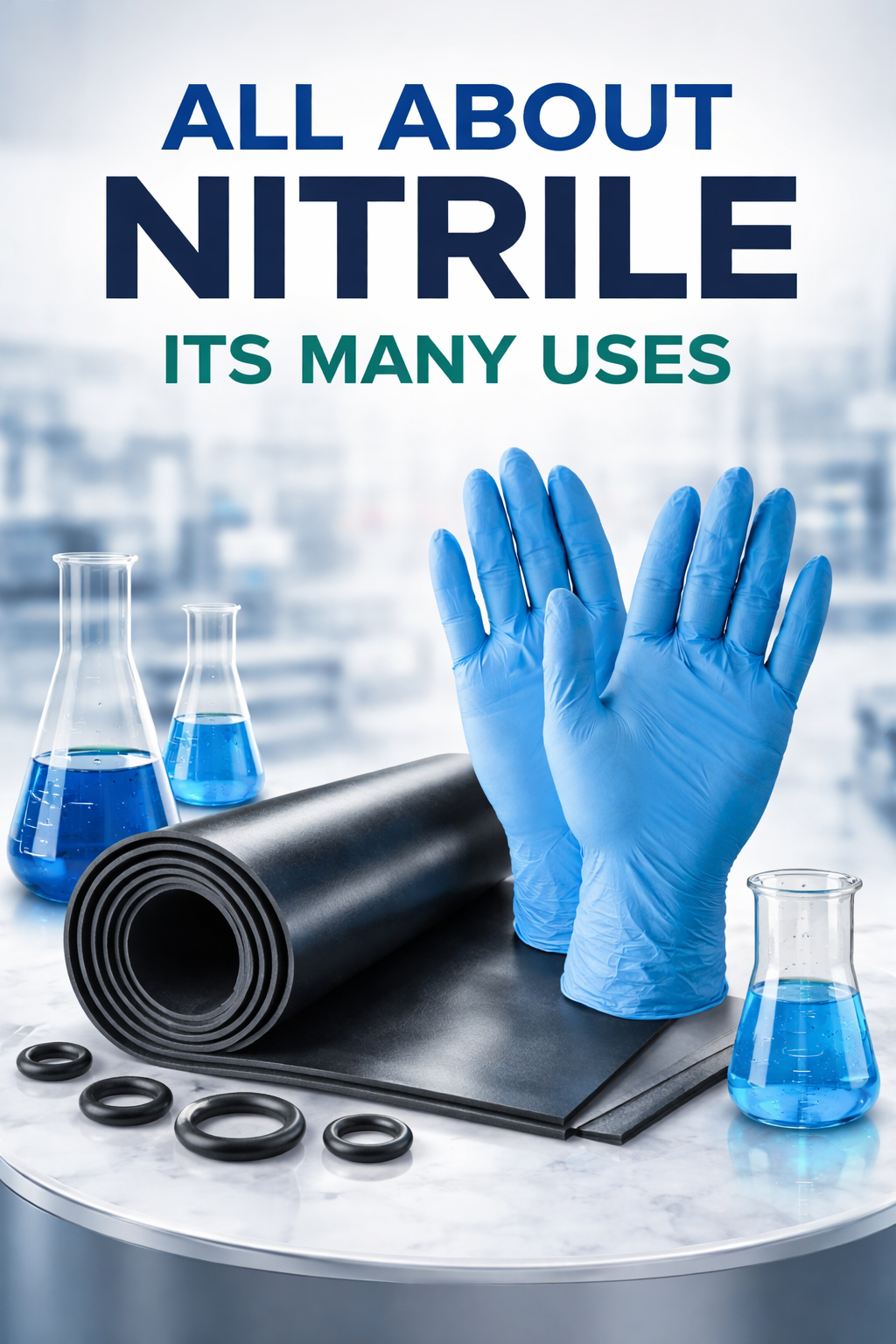

Material choice is paramount across a vast array of industries, and modern technology provides us with more and better options than ever before. One such material that has diverse applications is nitrile rubber.

What is Nitrile Rubber?

A synthetic (man-made) rubber, nitrile’s formal name is NBR or Nitrile Butadiene Rubber. It’s also known as Buna-N and acrylonitrile butadiene rubber; it is a copolymer of acrylonitrile (ACN) and butadiene. It has unique properties in that it is highly resistant to oils, fuels, and an array of other chemicals.

Acrylonitrile or ACN is a colourless, toxic and volatile liquid that is also known as vinyl cyanide. With a pungent onion-like odour, it is intrinsic to the production of plastics and acrylics, including resins, rubbers, and textiles. In nitrile, it helps balance chemical- and oil-resistance with flexibility.

Butadiene, also colourless, is a highly flammable gas that is derived from petroleum. It is critical to the production of plastics and synthetic rubber. It provides nitrile with resilience and elasticity.

Unlike its components, nitrile rubber is extremely stable and non-toxic. The percentage of ACN in nitrile can vary between 18% and 50%; this influences the properties of the final nitrile rubber produced. A higher percentage of ACN increases the rubber’s resistance to oils and chemicals; a lower percentage of ACN delivers higher flexibility at lower temperatures.

The Development of Nitrile

In the early 1900s, European researchers sought to develop a synthetic alternative to natural rubber (which is harvested as latex from rubber trees) that would be resistant to fuels and oils.

Nitrile rubber was developed for the first time in 1931 and was first commercially produced in Germany in 1935 with materials sourced in Polish coalfields.

Thanks to its high resistance to petroleum-based materials, this synthetic rubber was soon used widely in industrial, automotive, and military applications during the Second World War.

Technological advancements over the last century have expanded the versatility of nitrile, and it is now considered a staple in the manufacture of products requiring mechanical and chemical durability, as well as providing an alternative to natural latex rubber.

Key Properties and Benefits of Nitrile Rubber

Nitrile is ideal for many applications as it possesses a unique set of properties:

- Oil resistance

- Fuel resistance

- Temperature resistance

- Heat resistance/temperature versatility

- Strength

- Durability

- Puncture resistance

- Tear and abrasion resistance

- Chemical resistance, including to caustics

- Ageing/degradation resistance

- Wide availability

- Cost-efficiency

- Some nitrile gloves may be recyclable

Limitations of nitrile include weaknesses in terms of poor flame-resistance, limited flexibility at very low temperatures, poor reaction to UV, sunlight, and ozone, and hazardous decomposition of the rubber if exposed to solvents, chlorinated hydrocarbons, and some chemicals, including nitric acid. It is also not biodegradable and represents a significant environmental burden.

Applications and Uses of Nitrile

- Automotive industry – oil seals, gaskets, engine hoses, o-rings, transmission belts, and other parts

- Printing industry – ink rolls/form rollers

- Aerospace – self-sealing fuel tanks and bladders

- Textiles – fabric waterproofing and finishing

- Safety - nitrile gloves are popular for their toughness, puncture-resistance, and hypoallergenic properties (as opposed to latex). They are widely used in medical, surgical, and other healthcare settings, laboratory settings, cleaning, emergency services, manufacturing and automotive, hairdressing, and more.

- Manufacture of synthetic leather, floor mats, cable jacketing, footwear, moulded goods, sponges, pigment binder, and adhesive preparation

- Nitrile foam, which is used in pipe insulation, vibration-damping pads, sports equipment protective padding, and more.

Conclusion

Nitrile is but one type of rubber, but it has diverse applications across a vast number of industries. Resistant to fuels, oils, many chemicals, and abrasion, it is the gold standard material in many sectors for disposable gloves and a foundational material in personal protective equipment.

Muhammad Manan

Muhammad Manan