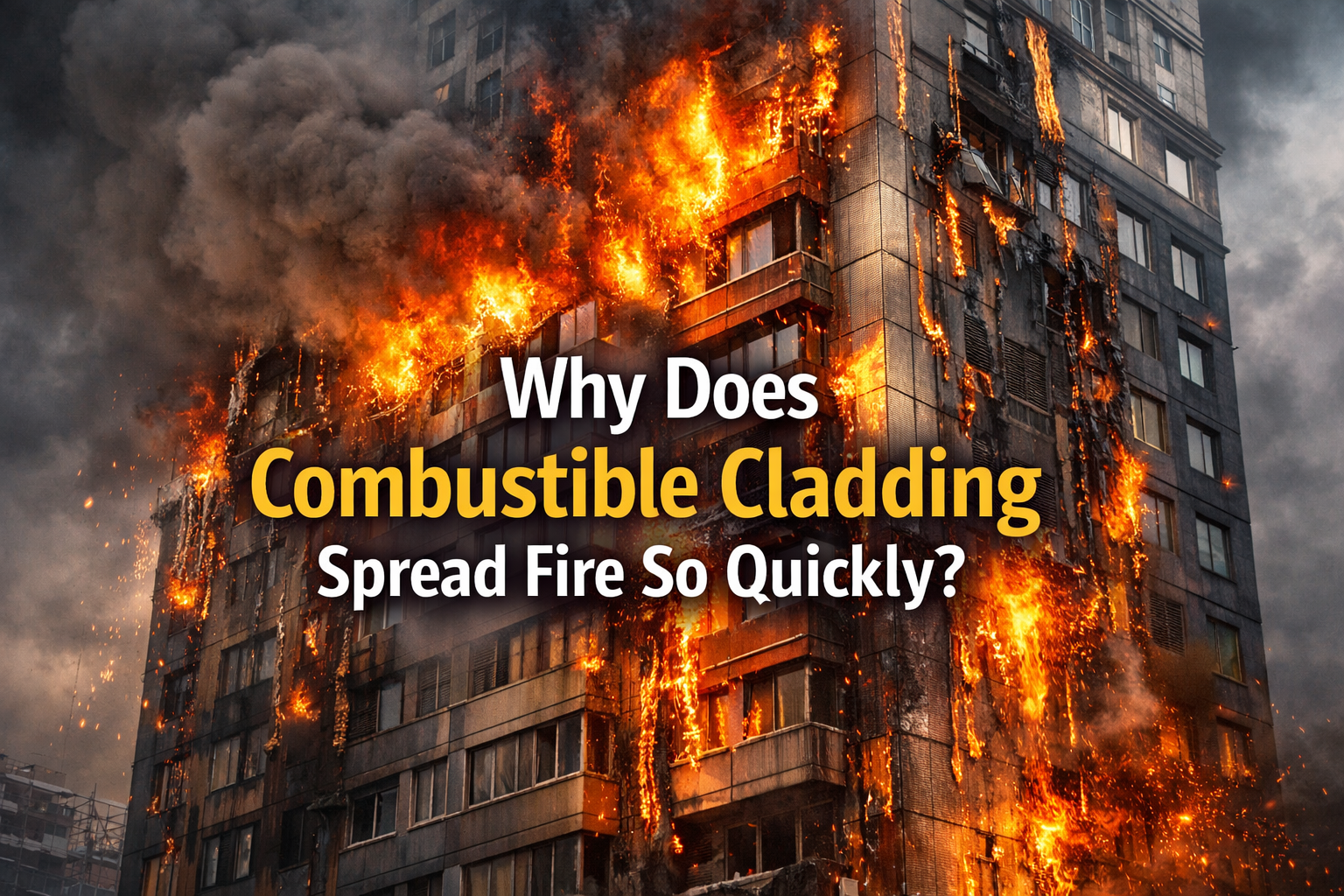

Fire is a major risk to property. From bushfires to fires that begin in houses or apartments due to faulty electrical systems and appliances, dropped cigarettes, or errant candles, the materials a building is constructed from can make the critical difference between containment and catastrophe.

Key Takeaways

- Fire risk is dramatically exacerbated in any building that uses combustible materials, and exterior cladding systems that use combustible cladding are at extreme risk.

- Combustible cladding ignites and contributes to the spread of flames. It poses a major safety risk, yet remains in place on many older Australian buildings.

- Cladding remediation for older buildings that have combustible cladding materials installed is extremely important. Choosing DtS non-combustible aluminium cladding is the gold standard and represents a cost-effective, long-term solution.

The construction industry and high-rise building owners and occupants globally were rattled when, in late November 2025, Hong Kong experienced the world’s deadliest residential building inferno since the 1980s.

More than 160 people perished in a high-rise estate that was undergoing significant renovations, as seven of eight thirty-one-storey buildings in the Wang Fuk Court complex burned over almost two days.

Various site safety compliance failures contributed to the spread of flames, including:

- Bamboo was used as a scaffolding material on all eight buildings

- Protective nylon netting on scaffolding did not meet fire-safety standards

- Polystyrene panels covered and blocked the windows

Forensic investigations thereafter showed that the fire ignited on a lower-level scaffolding net. The polystyrene foam panels covering the windows quickly caught fire, and the flames rapidly spread, blowing out windows and jumping between buildings with the assistance of high winds. More than 2000 firefighters took a day and a half to extinguish the blaze.

While this incident was caused by temporary installations related to the renovation project, it illustrates and highlights the fire risk posed by polystyrene foam – which is a component of some types of combustible cladding.

What is Combustible Cladding?

Cladding is the outside “skin” of a building; it provides weather protection, insulation, and design features.

Combustible cladding is a building façade material that was widely used in Australia and overseas since at least the early 1980s. Highly flammable, it includes materials that become incredibly hazardous in the presence of intense heat or open flame. These materials include (but are not limited to) timber weatherboard, certain types of aluminium composite panels, and expanded polystyrene cladding.

Combustible aluminium composite panels or ACPs are made from two thin sheets of aluminium that are bonded to a polymer core. The core is what represents a fire danger, and most polymer cores are polyethylene, which can be toxic when it burns. This was commonly used on buildings built before 2012.

Expanded polystyrene or EPS cladding is also combustible (and toxic when burned) as it can melt, shrink, or ignite when it is exposed to intense heat. As a thermoplastic, it behaves very poorly in fires and, despite potentially being infused with fire retardants, these may leech over time. It will burn in the presence of a large fire source. EPS was used extensively in the building industry in the 1990s and early 2000s and was typically covered with render to resemble rendered concrete.

Why Does It Burn So Fast?

Aluminium has a low melting point of approximately 660°C. Fire temperatures can exceed this markedly, and the aluminium covering on ACPs will potentially melt. This exposes the combustible core, which expedites ignition in the combustible cladding and the spread of the fire.

The Critical Importance of Recladding/Remediation

While the use of combustible cladding is now banned on new buildings in Australia, it remains in situ on many older buildings. Not only must building owners and managers identify whether their building has combustible cladding, but it’s crucial that they understand their legal and moral obligations and, if necessary, undertake remediation of this material through a recladding project.

Recladding also helps improve energy efficiency and updates the appearance of a building.

DtS non-combustible aluminium cladding is the benchmark for non-combustible building façades. These aluminium composite panels are made from thin aluminium sheets covering a mineral core. This mineral core is what provides unparalleled performance in terms of fire resistance and enhanced fire safety in buildings: it will not ignite nor contribute to the spread of flames.

Engineered specifically for the Australian market and designed for Australian conditions, ALPOLIC™ NC/A1 stands head and shoulders above competitor ACP products. There is no better choice for your recladding project.

Final Thoughts

Architects, builders, developers, property managers, and property owners must understand what combustible cladding is, its risks, its presence in their properties, and the legal obligations they are bound by. Recladding with a DtS non-combustible aluminium cladding product is an important way to remediate older, objectively unsafe buildings to reduce fire risks and achieve an outstanding result in terms of safety, compliance, performance, and visual aesthetics.

Muhammad Manan

Muhammad Manan